Task description

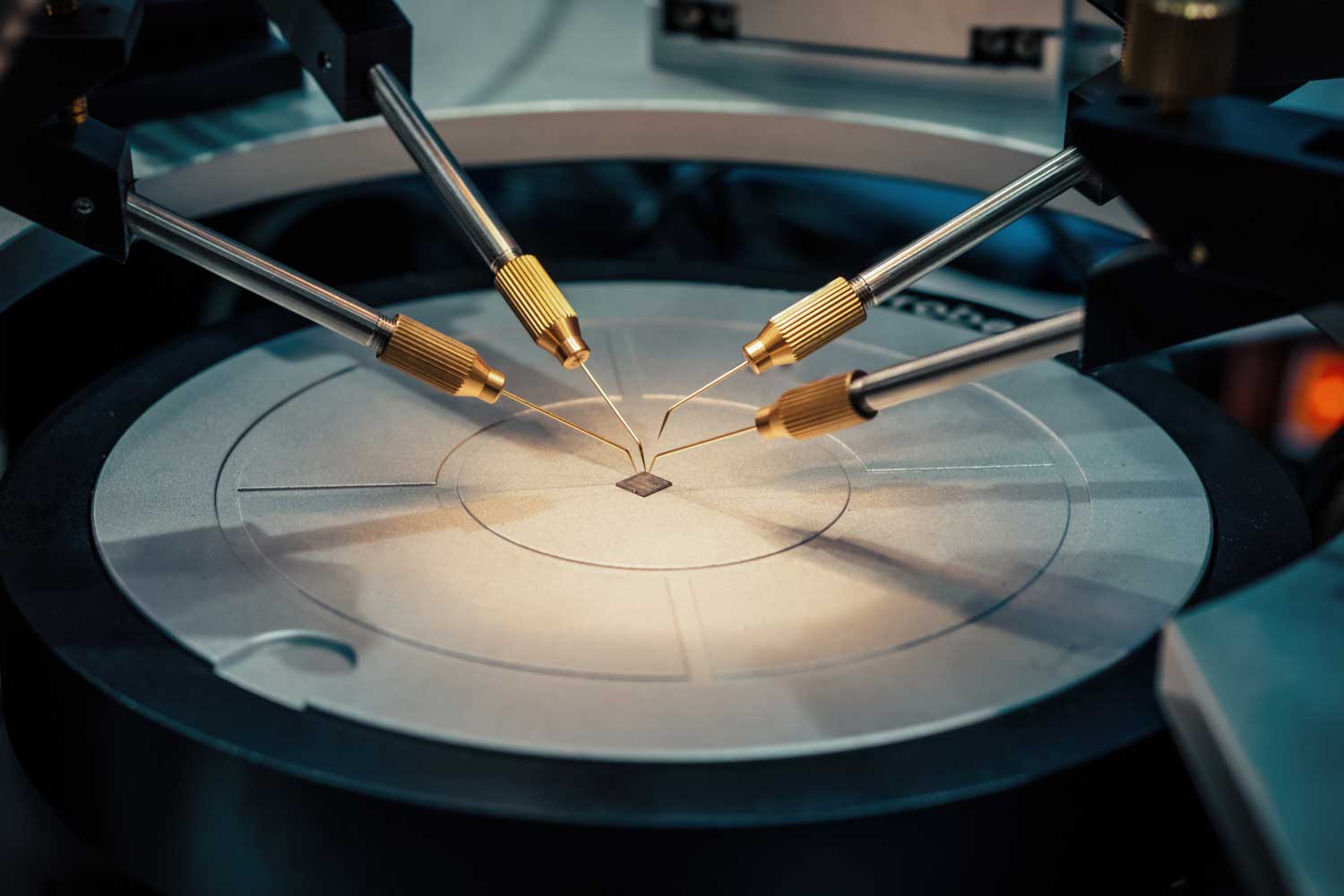

To validate the improvements in their design, a high-end power integrated chip designer wants to design a test jig to the use in the test lab.

In this new design, the IC generates a high level op heat while it is powered to maximum, which needs to be dissipated quickly to prevent damage of the part.

The jig is manually operated, the loading and unloading of the samples are done manually. A maximum of 20 ICs are expected to be tested on the jig per day.

Responsibilities

Design and fabricate the mechanical structure of the test jig. The important points are the electro static protection of the IC, >98% contact between the heatsink of the IC and the heat receptor of the jig without any contact gel.

The electronics, test software, power supplies and ICs to test will be provided by the customer.

Deliverables

The deliverables are

- The design drawing of the jig.

- A fabricated, assembled and tested sample of the jig.

- Release test reports.

- Component list and source of the standard components used on the creation of the jig.

- Test reports of 10 ICs.